In our June meeting we discussed different water related projects and tried different water balloon launchers to learn how they worked. Besides the classic surgical tubing slingshot method of shooting water balloons that Boyd, Elise, & Jim brought, we also looked at a pressurized water cannon that Rebecca & Chris built.

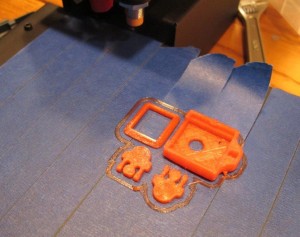

The water cannon, pictured to the right, was made from 2” pvc pipe and then used a bicycle valve stem to pressurize the main chamber. By opening the 2” pvc valve after pressuring, the burst of air propelled the water balloon… well initially 40-50 feet in prototype testing. But by correcting the launch angle with the help of the other folks there, a smaller volume of water for the cushion, and increasing the pressure with the bicycle pump we discovered that it easily went into the next city block. Not sure exactly how far it will go since it was hitting tree branches down the street.

After making sure anyone that wanted to (and a few that didn’t) were drenched, we decided that this would be our next build that we could show off at the Greencastle Farmer’s Market. More details soon!