This year we decided to pitch in and help Main Street Greencastle’s Santa in the Park project by making holiday ornaments to give away in Santa’s gift bags. We’ve held classes in making holiday ornaments before, so it seemed like a natural fit with one big difference. Instead of making 5-10 ornaments designed by class attendees, we needed to make 500 ornaments for the gift bags in 2 weeks or less!

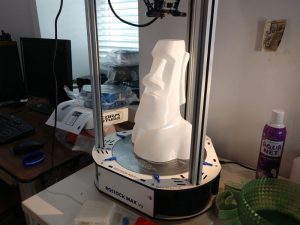

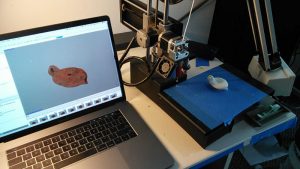

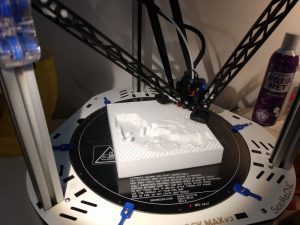

3D printing the ornaments, which we’ve done in our classes, was out due to the time constraint. Recently I helped a local entrepreneur make his parts for a new product idea on our laser, creating a little over 150 pieces in 15 minutes. They needed to be extremely precise and were slightly smaller than ornaments, but that had me thinking this was the way to go. What we needed was a simple to engrave & cut design that could be done in a reasonable length of time.

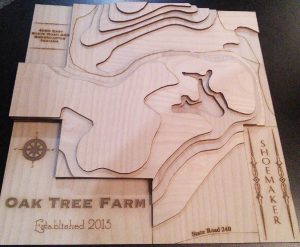

A local high school student, Hyrum Hale, came up with design that with a few modifications we could use. Our first prototype in green acrylic looked nice but wasn’t really visible on a tree, plus enough acrylic was hard to find due to Covid. Getting it to engrave/cut quickly required additional work; size of the ornament, material choice & availability, laser settings, and laser bed calibration/set up all were factors that determined time per ornament, quality, and repeatability. Making 500 items of anything means you learn a lot!

Although the cutting/engraving time was still substantial, we made the deadline and are really excited for our first time doing this. There’s a few extras at the Makerspace if you’d like one. We’re also already thinking about a new design for next year…