It started right after some donated glass fusing and slumping equipment, more on that in a future post, that was dropped off at Castlemakers. Troy, one of our more creative members, came in during open shop night with a sheet of glass and asked what our laser engraver/cutter would do to it. Since I wasn’t sure, it seemed like the perfect opportunity to find out.

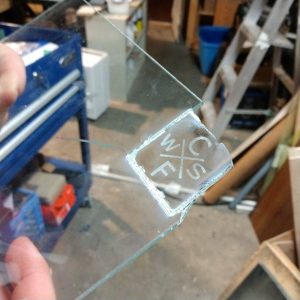

As it turns out it, it works great for etching! Power settings were modest and it gives a nice frosted look to the glass in a single pass.

Cutting really didn’t work though. We weren’t totally surprised that cutting would be more difficult, so started experimenting with the settings.

With wood or acrylic you can make multiple passes that will continue to cut through the material. A slower process, and sometimes takes refocusing the beam, but you can get the job done.

In this case we learned that the glass seems to absorb enough heat that it starts chipping and cracking. Perhaps it was the type of glass we were using, the glass used was a home project leftover. You can see from the picture it was not a clean cut and eventually created a longer crack in the glass. For now we’ll just manually cut glass until we get the new diamond saw setup. But we did learn how to etch using the laser!