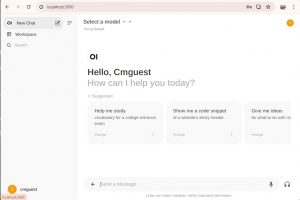

We held our first Artificial Intelligence (AI) / local Large Language Model (LLM) workshop at Castlemakers last Thursday. The focus was on downloading & creating an AI LLM local model using Ollama on a Windows PC, but given the target audience (those unfamiliar with AI) we used a ‘docker’ to keep it simple and spent a lot of time explaining all of the terms involved.

We decided to try a more cutting edge topic to expose people to AI and open source LLMs – plus help people realize it’s not as hard to do as it might seem. Having someone in our midst, Ian, that has been trying and using the different models also really helped! Folks attending had an option to take home a USB drive loaded with the software to install and try the software on their local computer at home.

If you’re interested in the topic, stop by Castlemakers during our Open Shop hours – we still have the system installed on a surprisingly small computer and with the Ollama interface you can try different open source LLM models on a local pc. It’s a great way to learn and experiment with something that will be effecting all of us already and in the coming future…