One of the things we always look forward to in the summer and fall is Main Street Greencastle‘s First Friday. With our location in downtown Greencastle on Franklin Street, we have a great location to have a hands-on, youth-oriented, ‘making’ project outside for people attending the monthly event. It’s also an opportunity for folks to checkout the makerspace & some of the current projects – although Open Shop times are another time good for that too.

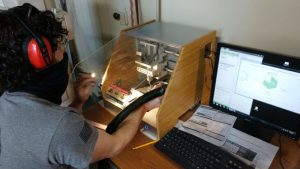

Projects change each month, but June was one of my favorites – catapults, something we’ve done a lot of with youth over the years. Given the age span of First Friday visitors and the time typically spent, this time we had them build chopstick and popsicle stick catapults – although one youngster was there for 1.5 hours working on his!

Plans are in the works for July 5th First Friday, please stop by. And don’t forget our annual Putt Putnam County event, which will be held on Friday October 4th from 6-8:30 pm. Last year we had 13 mini-golf holes built by people in our community. It’s not to early to think about building a hole and we’re always glad to you build one!