Last Saturday was Field Day for North American amateur radio, an annual ‘open house’ where 40k ham radio operators get out the radio equipment to make contacts and demonstrate to others how it’s done. We’ve helped out the local group PCAUXCOM the last few years by having a project to build or putting on an education session at their location.

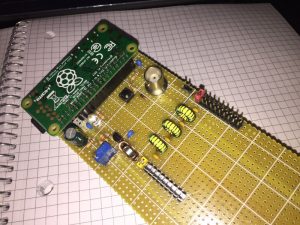

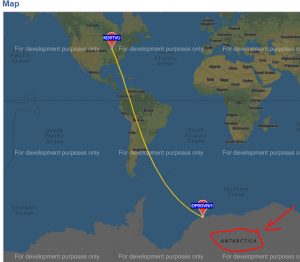

Last year we did something on using WSPR with a Raspberry Pi, so for this year we talked about listening to amateur radio satellites and the International Space Station(ISS). Although we don’t currently have the equipment to transmit to a satellite, it’s not hard to listen with a handheld receiver or police scanner. We have hopes of someday acquiring the necessary equipment to be able to actually contact other amateur radio operators using one of the satellites, or one of the radios on the ISS.

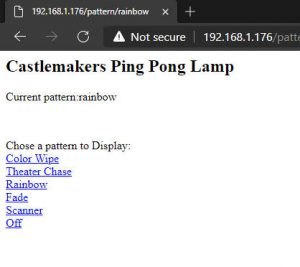

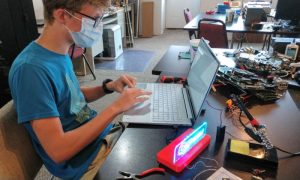

We also showed off a prototype satellite tracker that Ian has been designing that was made with 3D printed parts from the makerspace. While it’s still a work-in-progress, the prototype uses data from a satellite tracking app to move a mounted antenna to follow the satellite as it passes the sky overhead. There wasn’t an ISS pass but Ian was able to show how it tracked another satellite during the presentation. The major components were designed in Tinkercad, the same program we use in our Intro to 3D Printing class, and the tracking hardware is moved by software running on a Pi Pico!