After the big winds a few weeks ago, we decided to build some kites for our latest Castlemaker Kids project. For those not familiar with tetrahedral kites, the engineering behind the geometric design and history of Alexander Graham Bell’s involvement is interesting.

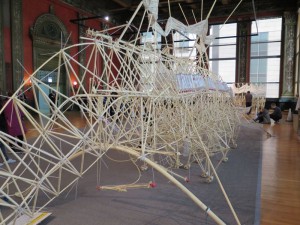

Alexander Graham Bell saw the Tetrahedral Kite as a way of getting to manned flight. Just before the turn of the 20th century, there was a big debate in the scientific community on whether human flight was possible. Kites were being used to test aerodynamics and flight stability for possible aircraft. After Lawrence Hargrave developed the box kite in 1893, Mr. Bell designed a tetrahedral kite in 1895, which was not only very stable but simple to expand and easy to fly. Mr. Bell wrote a National Geographic article in June 1903 on his new kite structure that explains the development and gives a comparison with other designs. He eventually created a steamboat towed 12 meter (40’) long 3,393 cell model in 1907 that carried a man 51 meters (168’) above the water!

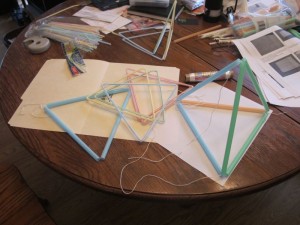

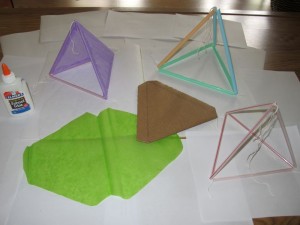

There are lots of variations today – the design we chose was built using drinking straws, string, and tissue paper (Tyvek also works). Individual tetrahedrons are made out of straws, tissue paper is put on 2 sides, and then they are tied together in groups of 4 to make a building block. The 4 cell model can fly by itself but if you get ambitious 10 cell modules work well too, all of which could be attached together into larger tetrahedral kites. Instructions for a simple 4 cell model can be found here, but it can be tailored to the supplies available and what you’d like to build. To help with the kids’ attention span (and time constraints) we stayed with a 4 cell model.

Finding non-bendy straws locally turned out to be a challenge, each 4 cell module takes 24 straws. The rest of the components are pretty straight forward, it’s just a matter of time and patience to assemble a kite. Once you figure out the pattern, the most difficult part is tying together the individual tetrahedrons with the string, in the version we used. There are several other versions if you search the internet, including one that uses flexible drinking straws, but the individual cells in the folding model are wired together. This makes assembly a bit more challenging and I found it harder to put and keep together, although the folding feature is nice.

A tetrahedral kite’s advantage is the low weight to sail ratio. Because of the shared trusses, as you add additional cells performance improves – what Bell saw in this design over other types of kites. And it’s easy to put multicolored paper on the kite, making a good looking kite. Don’t be surprised if you see some larger ones in the sky this summer in Putnam County!