We’re certainly excited about the new electronic equipment capability at Castlemakers, but the makerspace is not just electronics. One of our members, Dan, asked about making a bracket for his 2009 Triumph motorcycle to install an upgraded combination gauge for the stock speedometer & tachometer. We’ve only done a little aluminum machining, and it can be a very slow process, but if you don’t try you’ll never learn what you can do!

The original gauge included some warning lights, which he wanted, but weren’t part of the upgraded combo gauge so they were purchased separately. So Dan needed to create a new bracket design to hold the new gauge and lights.

I’ll let Dan take it from here:

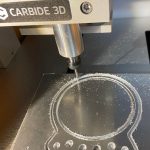

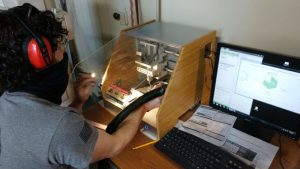

“I used Adobe illustrator to make a vector file of the shape I wanted, along with holes for mounting the bracket and indicator lights. I made a prototype on the laser cutter, and after a few small adjustments, we made the final version out of 3mm thick aluminum with the Nomad desktop CNC. There are still a few little tweaks I might make to get the spacing perfect (I ended up having to hand-drill one more hole for a button I had forgotten about), but I’m happy with the result. Couldn’t have done it without Castlemakers!”