Last year we had a Stereolithography (SLA) 3D printer donated to the makerspace and finally made time to get it up and running. The makerspace has been using using fused filament fabrication (FFF or FDM) since we moved into the physical makerspace and myself longer than that, but have resisted making the leap to other forms until now.

SLA so far has been pretty much what I expected: really great resolution and detail but it’s more complex dealing with the uncured resin. Post-processing time and especially cleanup is more involved than FFF, so processing 3D prints in batches makes a lot of sense. We haven’t experimented much with different resins, cost of the resin feels like it it is much more than FFF printing, although it’s a difficult comparison since SLA prints use a lot less resin and the uncured resin can be reused if you’re careful.

But oh, what resolution compared to FFF printing! You’re hard pressed to see the height layer lines when printing at 50 microns (yes, that’s .05 mm or .002″) and ours will let us print at 20 microns if you’re willing to take the time. X and Y dimensional resolution is at 75 microns (.075 mm/.03″), which is something you’re not going to see coming out of a filament nozzle printer. Of course for those levels of detail it will take longer to print, although the Digital Light Processing (DLP) system helps make the individual layer printing time much shorter.

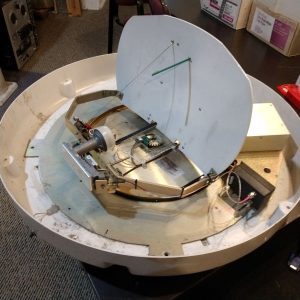

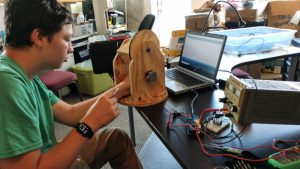

There’s some other minor differences, like the way you have to think about supports since the prints are pulled out upside down out of the resin tank. But it’s a nice tool and addition to the makerspace. Stop by sometime & we can show you what we’ve printed. We always have a class in November or December for folks to learn about 3D printing by making holiday ornaments, watch our events webpage or sign up for our newsletter to find out that date and more.